zPasteurAIzer

AI-enabled quality control in tunnel pasteurizersIn the food and beverage industry many foods, beers and soft drinks need to get pasteurized, a process that holds a significant role in the quality and taste of the final product but is difficult to monitor due to the process nature. We will develop an AI-enabled zApp that upgrades the typical tunnel pasteurizers giving the ability to monitor the key process parameters and estimate live the pasteurization units of final products, through AI models being compatible with various pasteurizers, via easy setup from shop floor operators. The zPasteurAIzer will be a tool for pasteurization process monitoring, early detection of quality issues, and prevention of batches of defective products.

zPasteurAIzer has been selected as a winner project in the ZDMP Open Call 2. The Zero Defects Manufacturing Platform (ZDMP) aims at providing an extendable platform for supporting factories with a high interoperability level to cope with the concept of connected factories to reach the zero defects goal. In this context, ZDMP will allow end-users to connect their systems to benefit from the features of the platform. ZDMP has received funding from the European Union’s Horizont 2020 research and innovation programme under grant agreement No 825631.

Key objectives

Provide shop floor operators an easy to setup tool for real time quality control in pasteurization process

Estimation of the Pasteurization Units (PUs) of produced products based on virtual sensing techniques and ML models.

Open and generic approach - compatible with any tunnel pasteurizer used in packaging production lines independent to the legacy of systems and the produced product

Extend ZDMP’s scope to the food and beverage manufacturing domain, providing specific zero-defect solutions for pasteurization processes

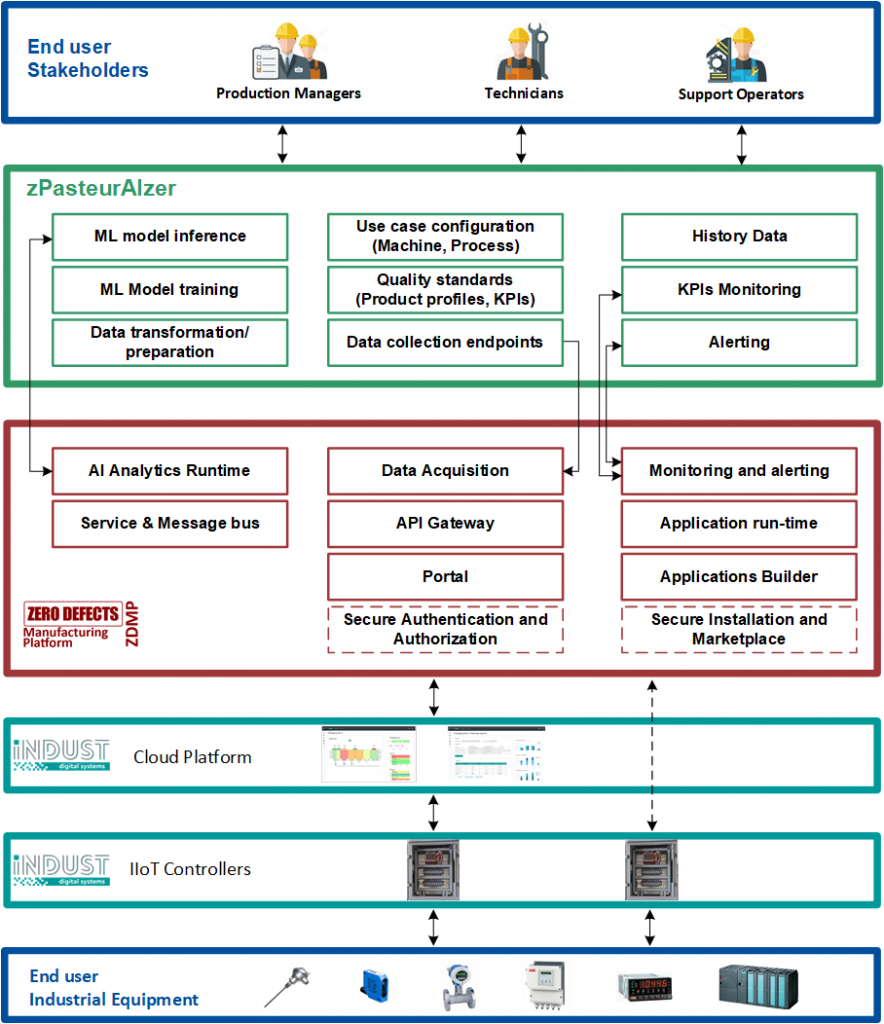

Architecture

Monitor in real time the key pasteurization process parameters and assure the quality standards.

Calculate the Pasteurization Units added to pasteurized products via AI-enabled models

Estimate the temperature at the cold point of the products during the intermediate steps of the process with virtual sensing techniques based on ML algorithms

Collect measurements for the temperature of sprayed water from machine's sensors and the process' states from the machines' PLCs

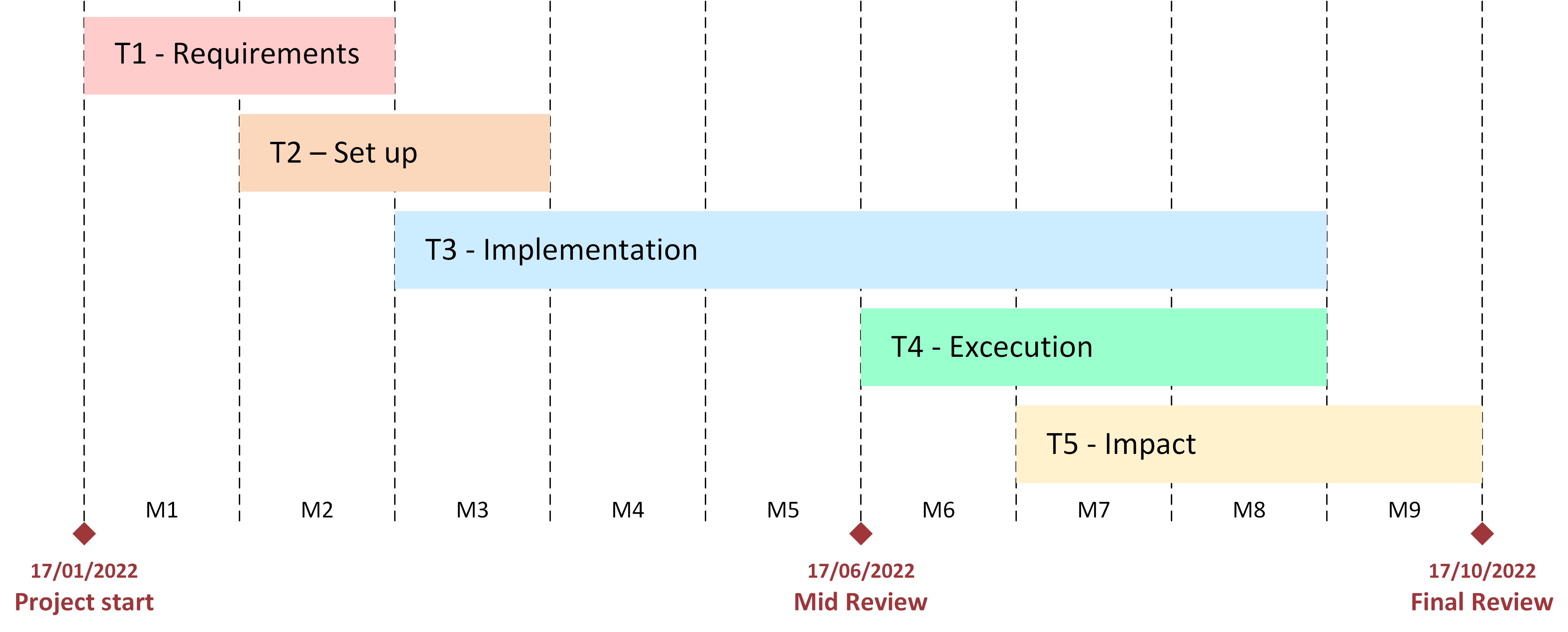

Project plan

Implementation milestones

MS1 - Architecture (M3)

The architecture plan of the whole zPasteurAIzer solution.

MS2 - Working Prototype (M5)

Alpha version of the zApp (a working prototype demonstrating the main end-to-end functionalities of zPasteurAIzer’s solution flow).

MS3 - Final Version (M8)

Final version of the zApp (fine-tunning during experimental validation use cases, integration with all zComponents and deployment to ZDMP)

Results

During the experimental period that lasted 7 months (M3-M9), our zApp detected in total 16 issues from which the operators found only the 1 of them with the manual thermograph samplings. As the machine operations assure the quality standards of the pasteurization process, no critical issues (out of the accepted PU limits), that lead to rejection or rework of the products, were detected. Most of the issues were minor (the PU was slightly over the ideal value), but we found 3 cases where, even though the PU was into the accepted limits, it was enough over the ideal value and the production operators asked the quality assurance department to check if it had any impact to the flavor of final product.

92.78 %

Total mean accuracy for PU prediction

2.17 PUs

Mean Absolute Error (MAE)

14.62 %

Total maximum error (deviation) amongst all the predictions

Partners

INDUST is developing an industrial digitalization system for monitoring critical parameters in production processes. It is an effective tool for shop floor employees to improve production efficiency and reduce costs. The system is installed on the production line, detects malfunctions and indicates to operators when and where to intervene to deal with problems immediately.

Role in the project:

- zApp design, development, testing and integration to the ZDMP

- zApp validation in real use cases on client's production lines

The IoT-Lab is a research laboratory at the University of Patras. The Lab focuses on the design, analysis and implementation of AI/ML algorithms, systems, applications, and testbeds for the Internet of Things. The activity of research team includes coordination and participation of R&D Projects, industrial research and development of innovative systems.

Role in the project:

- Dataset transformation for ML algorithms

- Design and development of the AI models for the zApp

This ZDMP sub-project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 825631.